Step 1: Design

Our process begins when we receive a Drawing or a concept for a part.

Step 2: Engineering

Through our initial review of the Project we will determine which Machine best fits the application and will take into account any required Tooling.

Step 3: Implementation

Communication with the Customer is critical at this stage as good problem solving techniques will make for a consistent process.

Step 4: First Article Inspection

During the First Article Inspection we’ll provide Quality documentation to the Customer based on the plan.

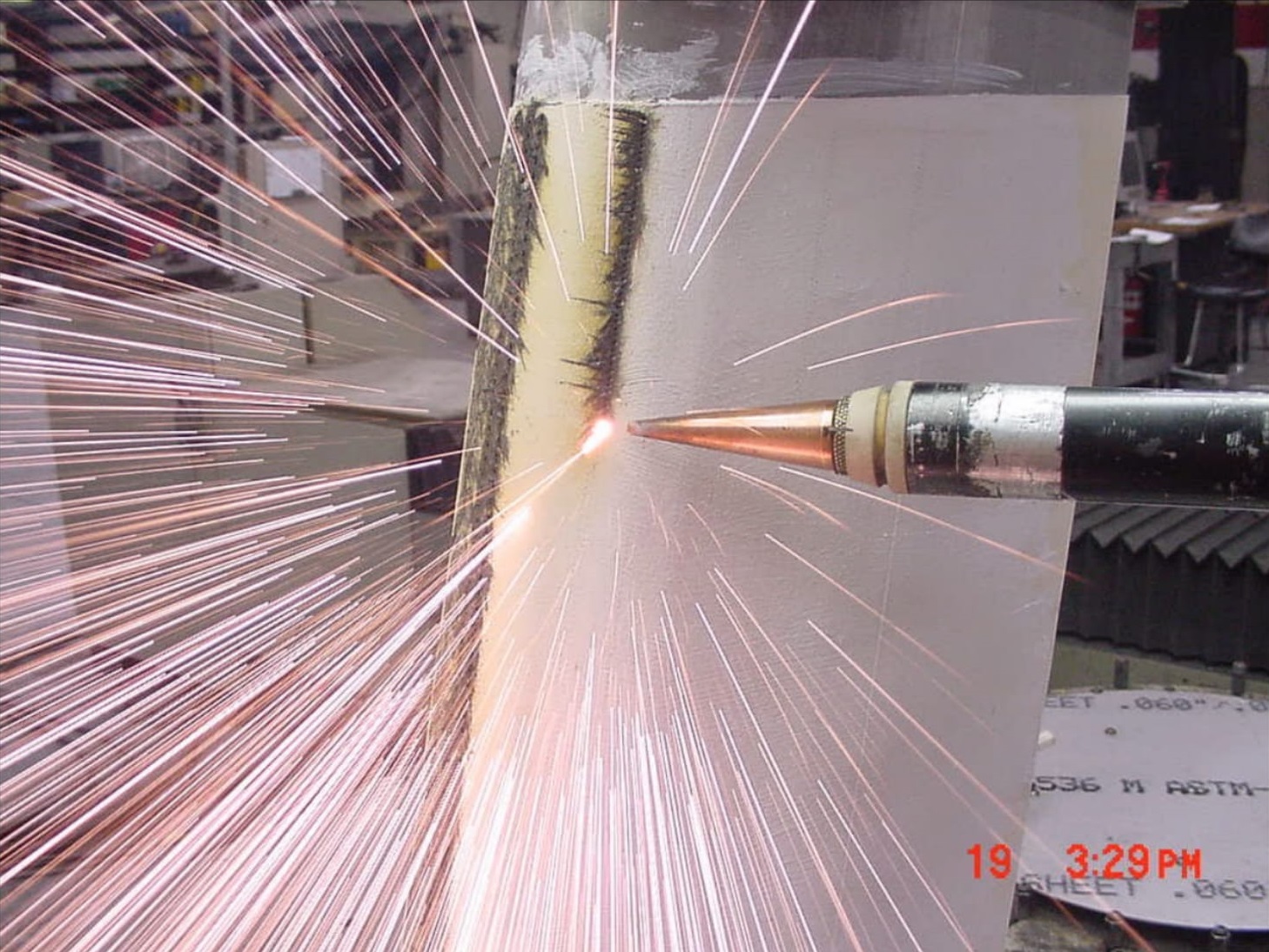

Step 5: Prototype

Prototypes may be the end result or the start of a project before going to production.

Step 6: Qualification

The part that is processed needs to meet the Customers’ expectations, so at this step, changes can be made prior to Production.

Step 7: Production

Production Parts will start after the Prototype and Qualification Parts are approved.